Soundproofing air vents is an excellent idea for several reasons. First, they help to provide additional airflow in rooms with small windows. This can help keep rooms dry and free of mold, for example. Additionally, this method can reduce noise for other reasons. It works by adding absorbent materials and walls to the vent, which bounce off noise.

Sound baffle

A sound baffle is a simple and effective way to soundproof an air vent without sacrificing the functionality of the vent. One way to do this is to cut a piece of plywood to fit the back of the vent cover. Then, use weather stripping tape or green glue to secure the plywood to the air vent cover.

You can also use a self-adhesive foam panel to soundproof your air vents. These panels are effective at absorbing airborne noise and vibrations, but you must make sure to put them deep enough into the vent. Simply covering the top 30cm of the vent with foam will not be effective.

If you have an older building, you might need to replace the entire air vent in order to soundproof it. Or, you might have a damaged one that needs to be replaced. In any case, it’s important to note that a sound baffle works by creating many bends in the vent. The bends in the baffle will absorb the sound, forcing it to travel a longer distance.

Another way to soundproof your air vent is by installing curtains or blankets. These products are easily available online and can be easily installed. Installing them will take no more than twenty to thirty minutes. Moreover, they don’t cost a lot. Once installed, they will thicken the walls and prevent noise from reaching other areas in your house.

Soundproofing your air vents can be a challenging task, but it’s not impossible. If you’re willing to spend a little money, you can try using a sound baffle on your air vents. But this won’t be 100% effective. You may also consider installing Rockwool ductslabs in the vent, which will absorb sound in the vent.

Flexible ducts

Soundproofing your air vents can be challenging, but there are several DIY solutions that will help you achieve the desired effect. The first method involves installing soundproofing material in the vent. This can be concrete, brick, or spray foam. You can also use striping tape to cover the edges of the vent cover. Once the soundproofing material is in place, you can apply an adhesive to close the duct.

Another method is to use a duct liner. This is usually inexpensive and can cover most air vent ducts. This method can help reduce noise from the vent by creating bends in the duct. These bends make it difficult for sound to escape the duct.

Another soundproofing option is to use flexible ducts, which are useful for soundproofing air vents. They can effectively reduce the noise levels in the space. As a bonus, they can be installed without tearing up the existing ductwork. However, be sure to hire a professional to do the work. The HVAC system is a complex system with many components.

Incorrectly installed flexible ducts can create a noise problem. The bends in flexible ducts cause sound waves to bounce back and are reflected, losing energy before reaching the vent. Aside from soundproofing your air vents, the flexible ducts should be installed properly to maximize soundproofing effects.

There are many types of flexible acoustic ducting. Some are made from aluminum and stainless steel, and others are made of PVC and vinyl. These ducts are commonly used in various residential settings.

Sound maze

Creating a sound maze for an air vent is a great way to reduce noise in a room. The first step is to cut a piece of plywood to fit inside the vent. Cut off about 30% of the end to fit the vent properly. Next, glue on pieces of acoustic foam. Repeat this process until all pieces are attached.

Using the right materials is essential to soundproof your air vents. It is important to choose materials that will minimize sound reflection, as well as those that will not affect air flow. Sound mazes are a great choice because they won’t block the flow of air but will significantly lower the sound level in your room.

The sound maze can also be made out of plywood, foam tape, or a combination of these materials. Then, you’ll need a screwdriver and a measuring tape. This soundproofing solution will reduce the noise in your room, while allowing for efficient heating and cooling.

Another effective soundproofing method involves blocking the air vent. The sound waves must travel through the plywood in a zigzag pattern in order to make it through the vent. This method is known as air vent occlusion. By blocking the vent, the sound will not be able to escape. The sound will be muffled and will not be reflected off the walls, which makes it a great choice for homes with air vents.

Creating a sound maze is an easy DIY project. It only requires a little time and requires a workspace. The sound maze is a great way to reduce noise in an air vent. It is also a great option for businesses that need to soundproof their vents.

Rockwool

Unlike fiberglass, which comes from non-renewable energy sources, Rockwool is made from natural rocks. This gives it high thermal efficiency, which can lower your energy bills. In addition, it helps minimize noise pollution by blocking sound waves and dull vibrations. Rockwool is also eco-friendly, since 75% of its material is recyclable. Its durability and resistance to damage make it a great choice for air vents.

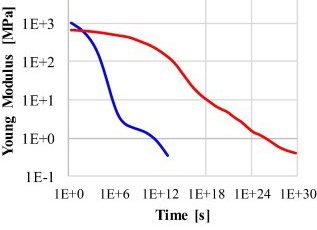

Compared to fiberglass and glasswool, rockwool is less effective at absorbing low frequencies. Although the two are similar in composition, they have different NRC ratings, making them not entirely equivalent. Generally speaking, glasswool is better at absorbing lower frequencies, while rockwool has higher NRC values. Fiberglass is also easier to install and comes in rolls, which can be easily fit into wall cavities.

Rockwool is more expensive than fiberglass but offers superior soundproofing and insulation. It is easier to cut, is firmer, and is more durable than fiberglass. In addition, it is stronger than fiberglass and has a longer lifespan than fiberglass. It also has good ventilation properties and does not encourage the growth of mold. On the other hand, fiberglass can cause health risks and isn’t as breathable as rock wool.

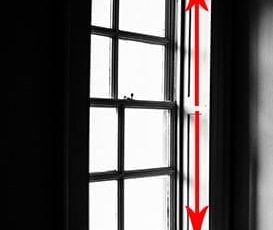

Soundproofing air vents can be inexpensive and easy to install. Just make sure to select the right material and measure carefully. It’s essential to ensure that the plywood is a half-inch thick and fits snugly inside the vent. Ensure that the plywood has enough length to accommodate the foam and soundproofing material. You can also use thin acoustic foam, such as Silverstone, which is only 0.15 inches thick. It won’t take up a lot of space in the vent, and you can cut it with a utility knife and scissors.

Blocking an air vent

Blocking an air vent will reduce the sound that is produced by a vent. You can use brick or concrete to block the vent. Alternatively, you can use spray foam. If you want a more complete soundproofing solution, you can cover the vent with a thick material. In addition to blocking the noise, the material will also reduce air flow.

Soundproof curtains are another option for soundproofing. You can install them on the curtain rail above the air vent. The curtains can be made of thick materials, which will dampen the sound vibrations. You can find these curtains at interior decor stores, as well as online. This method can also be a temporary solution.

Acoustic foam blocks aren’t as common as foam panels, but they can also be used to block an air vent. These blocks are large enough to completely cover the vent. To block it, measure the opening of the vent and cut the foam to the size needed. Once the foam is in place, press it against the sides of the vent. This will create a maze that prevents the sound from escaping.

Blocking an air vent is a relatively easy DIY project. If you’re not sure about DIY work, you can use drywall to cover the vent. This is an easy and temporary solution until the impact of the material is determined. Nevertheless, it’s important to consider the safety risks associated with this project.

Although the blockage of an air vent does not provide an effective soundproofing solution, it is still a viable option for some applications. Blocking an air vent may decrease the amount of airflow, which makes it difficult to maintain a consistent temperature. Also, cold air that travels through the blocked air vent will heat up slightly when passing through soundproofing obstructions.