A variety of options exist for floor soundproofing. These include Felt underlayment, cork flooring, and interlocking floor mats. The right choice for your space will depend on its soundproofing needs. If you have an existing floor, you can consider these alternatives to mass-loaded vinyl.

Interlocking floor mats

Interlocking floor mats are an easy way to soundproof your floor. These mats are durable and feature a non-skid texture. They connect together just like puzzle pieces and can be disassembled just as easily. They can be used for a variety of applications, including gyms, play areas, and garages.

While these mats are not effective in providing full sound deadening, they can be an effective addition to other soundproofing materials. Besides carpet, these floor mats come with a softer layer of felt that will absorb some of the noise. This layer is also less expensive than soundproof foam panels.

If you are looking for a cheaper soundproofing solution, you should look into interlocking floor mats. These are inexpensive and easy to install. Just ensure that you purchase enough mats to cover the floor. You can even stick these tiles to the underside of your carpet.

Another option is folding gym tumbling mats. These mats are available in 15 brilliant colors. They are made from a soft EVA foam core and are lead and latex-free. They are waterproof and stain-resistant. They are also available in a variety of sizes.

Rubber mats are also an excellent choice for soundproofing your floor. However, they are not as absorbent as foam or memory foam. They are also not as resilient as foam, so it’s important to get the right one for your room. If you don’t want to spend a lot of money on rubber mats, you can choose a thin layer of rubber underlay under the mat. This will help absorb the impact noise that is generated by the feet.

If you are trying to install floor soundproofing but are unsure how to go about it, consider rubber mats. They are a subtle solution that is cheaper than an underlay. They are flexible and dense enough to dampen the sound that comes through the floor, but do not have any gaps that could lead to safety hazards.

Felt underlayment

Felt underlayment for floor sound proofing can help you reduce the noise in a room by absorbing sound and heat. It is suitable for use under all types of flooring, such as hardwood, carpet, laminate, or engineered wood. However, you must keep in mind that felt underlayment is not waterproof. Consequently, you should install it with its felt side facing down.

Felt underlayment is a cheaper option compared to other floor soundproofing materials. It is also easy to install and remove. Felt is also eco-friendly as it is often made from recycled materials. However, it may not be suitable for high-humidity climates.

The STEICO wood fiber underlayment is another option. It offers excellent noise-dampening properties and is suitable for nail-down or glue-down hardwood floors. It provides a rigid surface and can even out uneven subfloors. However, some people find it too expensive for the benefits it offers.

The thickness of the underlayment is an important factor for floor soundproofing. Thickness is important because thicker materials can reduce noise, while thinner ones aren’t as effective. Moreover, it’s best to choose an underlayment product with a vapor barrier to withstand moisture and droplets.

Felt underlayment is also inexpensive. If you don’t want to spend a lot of money on it, try Roberts 70-193 Super Felt Underlayment. Its denseness is 14.5 lbs/ft. It works well under 5mm thick vinyl, LVT, or WPC/SPC planks. You may need to check with the manufacturer of the floor coverings before using this underlayment.

Installing underlayment is easy. It is easy to install, and requires no adhesives. In addition to this, it is moisture and mold resistant, so it can be beneficial for your flooring. Most people can handle this DIY task.

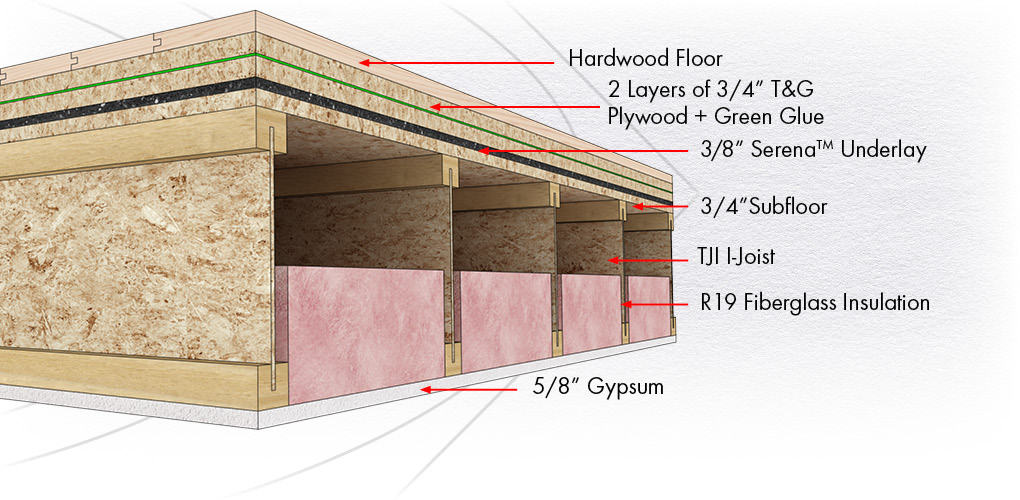

Plywood underlayment

Plywood underlayment is a thin layer that’s often used under flexible flooring. It absorbs sound but only moderately, which is why it’s often used with other materials like tar paper or red rosin paper to help reduce squeaks and echoes.

The best underlayment material is the one with a higher Sound Transmission Class (STC) rating than the flooring itself. If you have a hardwood floor, a STC rating of 40 or higher is appropriate. However, a high STC value is not a guarantee of effective soundproofing after installation. Underlayment thickness is also important, and you need to pick the right one based on the floor’s thickness.

It’s tempting to install free underlayment instead of purchasing a commercially available soundproofing product. After all, it’s inexpensive and can help block some noise. However, it won’t protect your flooring as well as soundproofing underlayment with a high STC and IIC rating.

Another option for floor soundproofing is to use cork flooring. While this product is easy to cut and assemble, it can crumble and is not as durable as the fiber-based materials. It also costs more than the fiber-based underlayment. One brand of underlayment with soundproofing capabilities is FloorMuffler UltraSeal. It’s thinner than the competition but offers superior sound absorption properties. It also features a moisture-resistant barrier that makes it easy to install.

Cork underlayment absorbs sound energy and is environmentally friendly. It can also act as a moisture barrier and smooth out uneven flooring. This product is not a good option for wooden floors, however. However, it’s an option for homeowners who don’t want to deal with the noise caused by footfall.

Cork floors

Cork floors are ideal for homes that want to reduce noise, but still want a comfortable floor. Cork is waterproof, hypoallergenic, and mold and mildew resistant. The material also retains ambient temperature, and the soft surface makes it comfortable to walk on. Cork also has a long lifespan, and it is also an eco-friendly material.

Cork floors are also an excellent choice for soundproofing a room because of their high noise absorption rate. According to the Noise Reduction Coefficient (NRC), cork absorbs over 70% of sounds and reflects only 30%. While a typical soundproofing product has an NRC of 0.4%, cork has a score of 0.7, which is close to that of mass-loaded vinyl.

Cork floors also reduce noise transmission between rooms and floors in multi-story buildings. This is because cork acts as a thermal barrier between rooms, and it prevents cracks in the subfloor from transferring to the finished floor. Also, cork is naturally non-slip, which reduces the amount of noise that can be transferred.

Although cork floors are an excellent choice for soundproofing, they cannot improve the IIC rating compared to foam or rubber underlayment. Since cork is very thick, the cork soundproofing properties are equal to about one-third of that of foam or rubber underlayment. The latter, however, has no airborne noise isolation advantage over cork.

Cork floors are also an ideal choice for radiant heat floors. The material’s excellent insulating properties also help increase energy efficiency. If properly installed, cork floors can last for up to 80 years. The material can be used as the main floor material or combined with cork underlayment for even better results.

Acoustic underlayment

The purpose of using an acoustic underlayment is to dampen the sound produced by floor vibrations. There are two types of sound – airborne noise and structure-borne noise. Airborne noise is the kind produced by conversations, televisions, and appliances. These soundwaves travel through the air until they strike a solid object, such as a floor or wall. Structure-borne noise, on the other hand, is the type produced by a collision between two objects. This type of sound is transmitted through the structure to the person on the other side. An ideal soundproof underlayment will block both types of noise.

In order to find an acoustic underlayment that provides the best noise reduction, building owners must do a thorough research before making a decision. They should ask questions about the material and the durability of the product. Then, they should ask their contractor about the advantages of the various underlayment types.

Acoustic underlayment systems are best used on floors. This type of underlayment is used to elevate the flooring above sleeper boards to create a dead air zone, which minimizes the transmission of vibrations. The main benefit of using an acoustic underlayment is that it is durable and non-slip, and it is also an environmentally friendly material.

Another type of acoustic underlayment is the mass loaded vinyl, which is usually not used for floor soundproofing. This product is used to shield noise from pipes and ducts. It also serves as a barrier for vibrations from machinery and other loud objects. Its high IIC rating is an additional benefit.