If you’re looking for a way to reduce noise in your home, you may be wondering whether acoustic plasterboard is right for your home. This article explores the benefits of acoustic plasterboard and its cost. It also looks at the environmental impact of this type of wallboard.

Soundproofing materials

Acoustic plasterboard is thicker and denser than normal plasterboard. This is because it’s designed to reduce sound transmission. Some types also contain an extra layer of soundproof product on top of the board itself. Although both plasterboard types are available for your home, there are some important differences.

Acoustic plasterboard is more expensive than ordinary plasterboard, but it’s worth the extra money for peace of mind. It also makes walls more resistant to noise. It’s one of the most effective ways to reduce noise in your home. There are some key differences between the two types of plasterboard and it’s important to take into account these differences before deciding which is best for your home.

While both types of plasterboard offer a certain level of resistance to sound, the former is more effective at reducing noise transmission. The average plasterboard features a square or tapered edge. The square edge is suitable for jointing, skimming, and textured finishes. Using an acoustic plasterboard can significantly reduce the noise in a room by up to 36 dB. This represents a 90% reduction in noise levels.

Acoustic plasterboard is not as dense as normal plasterboard. It is a good choice for high and mid-range frequencies. It blocks most sound frequencies, while a second or third-layer of normal plasterboard doesn’t block much. If you’re looking to reduce the noise in your home, acoustic plasterboard can be a cost-effective alternative.

Acoustic plasterboard is made from Gypsum, which is soft but dense. It’s also thicker than regular plasterboard, so you won’t need to worry about sagging plasterboard. It also won’t expand and won’t need to be replaced as often. Its unique properties help block out unwanted noise, including impact, airborne, and structure-borne noise.

Acoustic plasterboard is not a do-it-yourself project, but it can help you improve the noise in your room. There are various different types of soundproofing plasterboard, and you should understand their advantages and disadvantages so you can make the right choice for your home.

Types of acoustic plasterboard

Acoustic plasterboards have a range of advantages that include soundproofing and limiting transmission of sound from one room to another. Some types offer additional benefits, such as impact resistance, which protects the board against damage caused by contact. Some varieties also have four-in-one properties, which provide protection from water and fire.

Depending on the application, these types are available in different thicknesses. Soundstop plasterboard, for example, is available in 13mm and 10mm varieties. It is used in proprietary building systems such as QuietZone, CinemaZone, and Partiwall. It reduces the transmission of sound and helps reduce the level of noise in rooms with multiple speakers.

Other uses include garage conversions, which create a versatile extra room in the home. This can be a useful room for children, a music practice room, or even a games room for the elderly. Adding acoustic plasterboard to a garage can also help insulate it better and deaden noise, preventing it from escaping through the walls and ceiling.

Another major benefit of soundproofing plasterboards is that they can help save electricity. This is because they prevent the vibration of sound, and their cores contain glass fibre or other additives. These plasterboards are often more expensive than other plasterboards, but they are much better than their counterparts in terms of soundproofing.

Fire-resistant plasterboard is another popular type. These plasterboards are pink in colour, and designed to burn slowly, which is perfect for areas where safety is of utmost importance. They can also protect against smoke and fumes. Moreover, these boards can be painted over to blend with the look and feel of the room.

Another type of acoustic plasterboard is mass-loaded. This one is heavier and uses a rubber compound to increase its mass and density. These materials are usually installed between the studs of a wall, and are very effective at absorbing sound. If you’re thinking of installing these boards in your home, make sure you choose the right one for your needs. You’ll be glad you did.

Cost of acoustic plasterboard

Acoustic plasterboard is an excellent soundproofing material that can be used in a variety of applications, such as ceilings, walls, and floors. It helps to reduce noise between rooms and reduce the impact of noisy neighbours. It can also be used on stud walls, which increases its soundproofing capabilities. It can reduce noise levels by as much as 42 decibels, which is a significant reduction compared to a ‘normal’ wall.

Acoustic plasterboard is also an excellent option for soundproofing existing walls. It contains rubber sheets that reduce the amount of airborne sound passing through walls. A professional tradesperson can advise you on the best soundproofing solution for your home. The cost will vary, however, depending on the structure of your house and the type of sound you are trying to block.

Acoustic plasterboard is available in two thicknesses. It can be as thick as 32mm or as thin as a thin sheet. It is usually used in conjunction with other soundproofing products, such as JCW Vibrablock, to increase sound insulation. It is relatively inexpensive to install. However, it is important to discuss its installation with a structural engineer.

Acoustic plasterboard can reduce sound and improve the productivity of your workplace or home. It is suitable for many substrates, and can be easily installed. This type of ceiling board can reduce the cost of installation by around $60 per square metre. It is easy to install, and the ceiling contractor usually supplies the tiles. They are typically installed within the ceiling cavity, or in the plasterboard wall. Alternatively, you can frame them off a concrete block wall.

Environmental impact of acoustic plasterboard

Environmental impact of acoustic plaster is one of the primary concerns of the building industry. In addition to soundproofing, acoustic plasters also improve aesthetics. While the original plasters were often made of asbestos, newer acoustic plasters are made of mineral wool or other inorganic blow-glass granulates. The plasters are applied at a thickness of about one-eighth of an inch. They consist of a base layer of absorptive substrate panels and a finishing layer. The first layer produces a first-layer system of sound attenuation, and a second finishing layer is added to provide even more sound reduction.

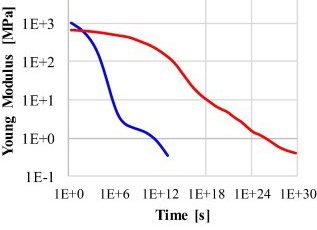

The thickness of the fibres determines the amount of sound absorption. Basalt and glass fibre reinforced plasters have similar absorption coefficients. In addition to their acoustic benefits, plasters differ in their durability and adhesion to masonry. In general, the strength and durability of the plasters are related to their binder.

Acoustic plasterboards can help preserve and enhance a historic building. One example is the Denver Union Station, a Beaux-Arts masterpiece in the heart of the business district. The acoustic plasters used by BASWA Phon preserved the original design and aesthetics while still enhancing the acoustic environment. In fact, the project was so successful that it won the RIBA House of the Year award 2017.

Several proprietary acoustic plasters were introduced in the 1920s. These included Macoustic Plaster, Sabnite, Kalite, Old Newark, and Wydak. In addition, US Gypsum produced Sprayo-Flake. While some of the materials used to manufacture these plasters are made from natural resources, they are harmful to the environment and human health.

While the use of mineral wool-based acoustic plasterboards can improve the comfort level of a space, they have a high carbon footprint. Using a bio-based acoustic plasterboard in place of mineral wool is a more environmentally friendly way to achieve this goal. It also reduces the use of paint, filler, and other building materials.