Soundproofing a truck cab can be done several ways. You can use silicone caulk and rubber pads to fix rattles. You can also use hard surfaces inside the cab to reflect noise. You can try cabinet walls, bare floorboards, or back sleeper seats.

Mass loaded vinyl

Mass loaded vinyl is a good choice for soundproofing a truck cab. It helps to eliminate airborne noise. Mass loaded vinyl is applied to the floor, door trims, and other areas that are exposed to noise. You can also use closed-cell foam to reinforce these areas. Once the mass-loaded vinyl is installed, the seats and carpeting can be reinstalled. The back wall and roof should be covered as well.

Mass loaded vinyl is more effective for soundproofing a truck cab than other products. Its thick composition and low resonant frequency make it the best choice for absorbing soundwaves. Besides, it also helps reduce the noise emitted from loose objects, like tires and cargo.

Mass loaded vinyl is made of 2 outer layers of vinyl and an inner core of calcium carbonate or barium sulfate. These layers are sandwiched together to create a rigid, but flexible material. It also absorbs sound waves, so they are reduced or completely eliminated.

Mass loaded vinyl is effective at reducing rattle noise and other noises that might otherwise be transmitted into the cabin. It can also be applied to the floors of the cab to cover the floor. It is important to clean the area properly before applying the material. However, higher quality materials cost more than cheaper ones.

When installing mass loaded vinyl for soundproofing a truck, make sure to use high quality products. You should also look for the STC rating of the vinyl. A higher STC rating indicates more effective noise blocking.

Constrained layer dampening fabric

The use of damping materials is an excellent way to improve the soundproofing of a truck cab. These materials are designed to absorb and reduce vibration of a vehicle’s body panels, which can result in high noise levels. There are many different damping systems available, including constrained layer damping, peel and stick damping, spray-on damping, and full panel damping. Each type of damping system has its advantages and disadvantages.

The most effective material for soundproofing a truck cab is a dense layer of mass-loaded vinyl. Its density and flexibility help block sound waves and reduce resonance. This material also blocks the transmission of airborne noise. It is also ideal for tackling the issue of airborne noise, as it can be adhered to the surface.

Soundproofing a truck cab can be an easy and quick process. The first step is to remove the floor trims and apply mass-loaded vinyl over the surface beneath the floor. If you have a bare floor, you can use closed-cell foam instead. Once the floor is soundproofed, you can put back the seats and carpeting. You do not need to cover the entire floor, and you can apply CLD to the interior walls as well.

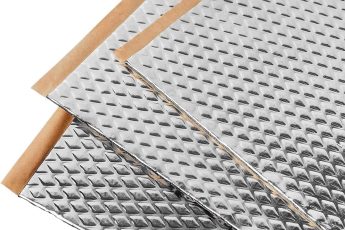

Another soundproofing method is to use a material called a constrained layer dampening fabric (CLD). This fabric is commonly referred to as a “Sound Deadener” and is made from butyl rubber. The base layer has a low stiffness, which helps it mold to irregular surfaces. The material is also lightweight, which makes it ideal for use in over-head applications.

Constrained layer damping is a popular method of soundproofing a truck cab. It is widely available and cost-effective. It is also thin and lightweight, making it an ideal choice for vehicle soundproofing. Although Dynamat is the most popular choice for soundproofing a truck cab, there are other CLD materials available.

Vibra Block(r) deadening sheet

Soundproofing your truck cab can be difficult without the right materials. You’ll need closed cell foam and CLD materials for the floors and doors. Once you’ve done this, apply mass loaded vinyl over the doors and trim it with closed cell foam. You’ll also need to soundproof the walls and roof.

Vibra Block(r) deadening sheets can be applied to any metal panel. These sheets can be laid out inch by inch, and the self-adhesive material will adhere to metal without tearing or pealing. You can apply the deadening sheet with a roller, and they won’t easily peel away.

The primary problem with truck cab sound is structure-borne noise. This is caused by the interaction of tires with the road, which is transferred into the cab through the suspension system. A good suspension system can improve the quietness of the cabin. You can also use a constrained layer damping material like Dynamat to combat airborne noise.

Using a noise machine to drown out distracting sounds

Distracting sounds from outside the truck cab can make driving a difficult task. Some sources of noise include open windows and poorly sealed doorways, and noise from the tires hitting the road. Cracks and holes in the cab can also let in the noise from outside. To reduce these distracting sounds, use a noise machine.

This noise machine is compact but quite loud. You can set it to play white noise, or you can customize the volume to suit your needs. It can be powered by a USB cord or a wall adapter. However, this noise machine hums slightly when plugged in, which can be distracting.

Sound machines can help truck drivers sleep and stay alert in busy environments. Some are portable and run on batteries. Others mimic different sounds, including waterfalls, fireplaces, and airplane cabins. One type features 29 sounds and can last for up to 12 hours.

While most noise machines have buttons on the front so you can control the volume, there are also smartphone-compatible noise machines that can be used on a mobile device. The buttons are easy to press, but may be difficult to read in the dark. The light from the phone may also keep you awake.

Using a noise machine is a great way to improve your concentration and relax when working. The noise machines play relaxing, soothing sounds. The sound quality is dependent on the quality of the speakers, so make sure you choose a machine with good speakers. Avoid those with crackling speakers, as they are distracting.

A noise machine can also help you sleep while driving. It works by drowning out different background noises. One of the best noise machines is a white noise machine, which produces white noise. Users can set the volume and tone to suit their preferences.

Using mass loaded vinyl to soundproof a truck cab

Mass-loaded vinyl, also known as CLD, is a great way to reduce airborne noise within a truck cab. It’s best applied to the floor and door trims for full coverage. For less critical areas, such as the roof and back wall, mass-loaded vinyl can be skipped. Afterwards, you can reinstall the carpeting and seats. The largest space for noise entry is the floor. The next most common problem areas are the doors and roof.

Depending on the volume and type of soundproofing material you choose, you may need to use more than one layer. Since trucks have different types of roofs, you may need to apply an additional layer of mass-loaded vinyl for a thick roof. However, if you have a thin roof, a single layer will do.

Soundproofing a truck cab is a great way to protect both the cab and the operator’s well-being. Noise can be distracting and stressful to a truck operator, and can even lead to hearing loss or other ear-related issues. Using mass-loaded vinyl to soundproof a truck cab can help minimize noise and protect the operator’s health.

Mass-loaded vinyl is one of the best materials for soundproofing a truck cab. The material is extremely versatile and flexible, making it easier to apply on the interior surfaces of a truck cab. Nonetheless, it doesn’t come cheap. You’ll pay between $280 and $300 for an inch-thick sheet of MLV.

Mass-loaded vinyl is not the same as ordinary vinyl, so it’s essential to choose high-quality mass-loaded vinyl. Mass-loaded vinyl should have a density of 1 lb or more per square foot. In addition, it should be odorless, as cheap vinyl produces an odor and is less effective than mass-loaded vinyl.